Self Fluxing Alloy with wear and corrosion resistant

Description

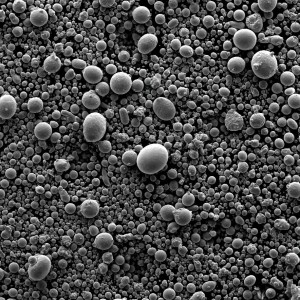

NiCrBSi series alloy powder with high hardness is the most widely used wear resistant and corrosion resistant alloy powder with low melting point and powder melting temperature. It has excellent self fusibility, wettability and spray welding performance. It is commonly used for corrosion resistant and wear resistant, especially for the preventive protection and repair of sliding wear resistant parts.

Similar products

| Brand | Product Name | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-Ni15 | NiCrBSiFe | |||||

| KF-Ni25 | NiCrBSiFe | |||||

| KF-Ni35 | NiCrBSiFe | 12 | NI563 | 65 | ||

| KF-Ni45 | NiCrBSiFe | 14 | 69 | |||

| KF-Ni55 | NiCrBSiFe | |||||

| KF-Ni60B | NiCrBSiFe | |||||

| KF-Ni60A | NiCrBSiFe | 335 | 15 / 2001 | NI167 / 1275 | 60 | |

| KF-Ni60AA | NiCrBSiFe | 335 | 15 / 2001 | NI167 / 1275 | 60 | |

| KF-300A | Ni60+35WC-Ni | 36 / 734 | WC562 | 81 | ||

| KF-300B | Ni60A+50WC-Co | 34 / 734 | WC487 | 89 | ||

| KF-300C | Ni60+35WC-Co | |||||

| KF-300D | Self-fluxing Nikel base Tugsten Carbide |

Specification

| Brand | Product Name | Chemistry (wt%) | Hardness | Temperature | Properties & Application | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Si | Fe | B | Ni | |||||

| KF-Ni15 | NiCrBSiFe | 0.15 | 5 | 2 | 5 | 1 | Bal. | HRC 15 | ≤ 700ºC | •Oxy-Acetylene, PTA, HVOF, APS, laser cladding, self-fluxing, spherical

•Glass molds, bearings •Low hardness, high toughness •Good corrosion resistance and wetability |

| KF-Ni25 | NiCrBSiFe | 0.20 | 7 | 2.8 | 5 | 1.5 | Bal. | HRC25 | ≤ 700ºC | •Oxy-Acetylene, PTA, HVOF, APS, laser cladding, self-fluxing, spherical

•Glass molds, bearings •Low hardness, high toughness •Good oxidation and corrosion resistance as well as wetability •Exellent machinability |

| KF-Ni35 | NiCrBSiFe | 0.30 | 9 | 3 | 5 | 2 | Bal. | HRC 35 | ≤ 650ºC | •Glass molds , bearings

•Pistons •Valve seats |

| KF-Ni45 | NiCrBSiFe | 0.45 | 13 | 3 | 10 | 2.5 | Bal. | HRC45 | ≤ 650ºC | •Glass molds , bearings

•Pistons •Valve seats |

| KF-Ni55 | NiCrBSiFe | 0.75 | 15 | 3 | 10 | 3 | Bal. | HRC 55 | ≤ 650ºC | •Molds

•Bearings •Pistons |

| KF-Ni60B | NiCrBSiFe | 0.80 | 17 | 4 | 15 | 3.5 | Bal. | HRC60 | ≤ 650ºC | •Fan blades

•Boiler tubes •Pistons |

| KF-Ni60A | NiCrBSiFe | 0.80 | 17 | 4 | 5 | 3.5 | Bal. | HRC 60 | ≤ 650ºC | •Oxy-Acetylene, PTA, HVOF, APS, laser cladding, self-fluxing, spherical

•Pistons, conveying rollers, wire drawing pulling wheels, extrusion screw •High hardness, wear and corrosion resistance |

| KF-Ni60AA | NiCrBSiFe | 0.90 | 17 | 5 | 3 | 3.5 | Bal. | HRC60 | ≤ 650ºC | •Oil coupling

•Conveyor roller •Wire drawing pulling wheels, •Extrusion screw |

| KF-300A | Ni60A+35WC-Ni | Ni60A+35WC-Ni | HRC65 | ≤ 600ºC | •Oxy-Acetylene, PTA, HVOF, APS, laser cladding, self-fluxing, spherical

•Wire drawing pulling wheels, blades, pistons, impeller •Better wear resistance than Ni60 |

|||||

| KF-300B | Ni60A+50WC-Co | Ni60A+50WC-Co | HRC65 | ≤ 600ºC | •Brick machine

•Sediment agitation •Extrusion screw •Agricultural equipment |

|||||

| KF-300C | Ni60A+30WC-Co | Ni60A+30WC-Co | HRC65 | ≤ 600ºC | •Oxy-Acetylene, PTA, HVOF, APS, laser cladding, self-fluxing, spherical

•Wire drawing pulling wheels, blades, pistons, impeller •Better wear resistance than Ni60 •Exellent particle and hard facing abrasion and errosion resistance |

|||||

| KF-300D | Self-fluxing Nikel base Tugsten Carbide | Proprietary | HRC65 | ≤ 600ºC | •Oxy-Acetylene, PTA, HVOF, APS, laser cladding, self-fluxing, spherical

•Wire drawing pulling wheels, blades, pistons, impeller •Better wear resistance than Ni60 •Self-fluxing •Exellent particle abrasion and corrosion resistance |

|||||