Rhenium bars High temperature alloys

Specification

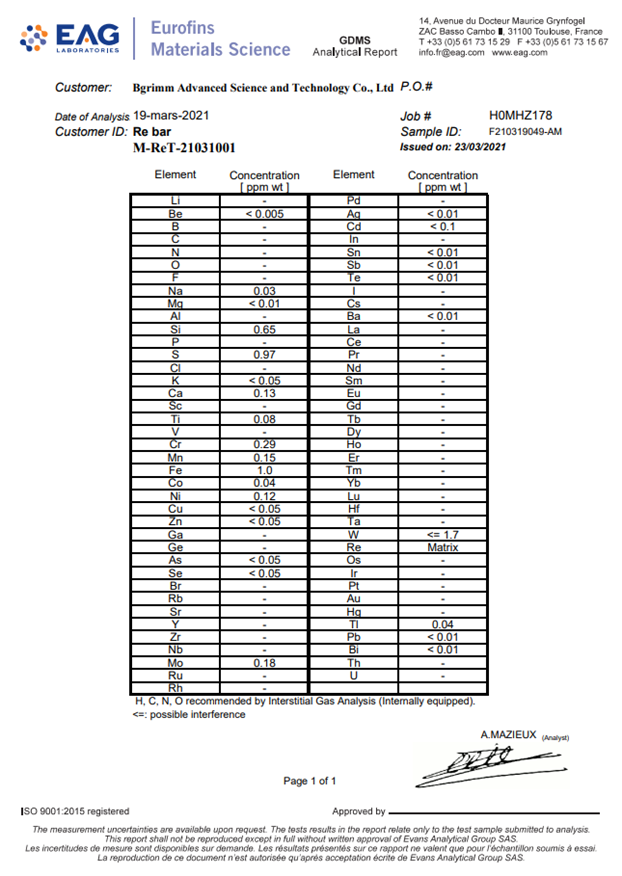

Thank you for considering our Rhenium bars, a high-purity additive used in the manufacture of advanced aerospace and aviation equipment. These bars are made from high-purity Rhenium, with a minimum purity of 99.99% calculated by the differential subtraction method and excluding gaseous elements. This high level of purity is essential for ensuring the reliability and performance of the final product.

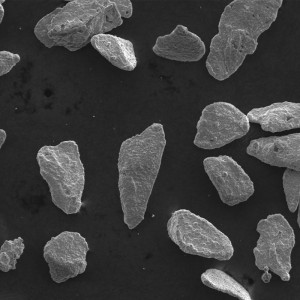

Rhenium bars are commonly used as single crystal high-temperature alloy additives, and in the manufacture of master alloys for modern high-speed aircraft engine components, aerospace equipment components, and other ultra-high temperature areas. They have a silver-grey appearance, and are available in a standard size of 15mm x 15mm x 500mm, or they can be customized to meet specific customer requirements.

To use Rhenium bars, follow these simple steps:

Preparation: Make sure you have all the necessary equipment and materials, including a furnace or other high-temperature processing equipment. Clean and dry all components to be used with the Rhenium bars to ensure optimal performance.

Loading: Load the required number of Rhenium bars into the furnace or processing equipment. The bars can be easily cut and machined to meet your specific requirements.

Processing: Process the alloy or material according to your standard procedures, incorporating the Rhenium bars as needed. The high-purity Rhenium will help to improve the strength, durability, and high-temperature resistance of the final product.

Finishing: Once the processing is complete, carefully remove any excess material or debris from the furnace or processing equipment. The finished product can be inspected and tested to ensure it meets the required specifications and performance standards.

Please note that Rhenium bars are a high-purity product, and proper handling and storage is important to maintain their quality and performance. Store the bars in a clean, dry environment away from direct sunlight, and avoid any physical damage or contamination.

Thank you for choosing our Rhenium bars for your high-temperature applications. We are confident that our high-quality product will meet your needs and exceed your expectations. If you have any questions or need additional information, please don't hesitate to contact us.

Chemical composition

|

No. |

Elements |

%wt |

No. |

Elements |

%wt |

|

1 |

Al |

0.0001 |

15 |

Ni |

0.0005 |

|

2 |

Ba |

0.0001 |

16 |

Pb |

0.0001 |

|

3 |

Be |

0.0001 |

17 |

Pt |

0.0001 |

|

4 |

Ca |

0.0005 |

18 |

S |

0.0005 |

|

5 |

Cd |

0.0001 |

19 |

Sb |

0.0001 |

|

6 |

Co |

0.0001 |

20 |

Se |

0.0005 |

|

7 |

Cr |

0.0001 |

21 |

Si |

0.0010 |

|

8 |

Cu |

0.0001 |

22 |

Sn |

0.0001 |

|

9 |

Fe |

0.0005 |

23 |

Te |

0.0001 |

|

10 |

K |

0.0005 |

24 |

Ti |

0.0001 |

|

11 |

Mg |

0.0001 |

25 |

Tl |

0.0001 |

|

12 |

Mn |

0.0001 |

26 |

W |

0.0010 |

|

13 |

Mo |

0.0010 |

27 |

Zn |

0.0001 |

|

14 |

Na |

0.0005 |

28 |

Re(substrate) |

≥99.99 |

|

Note: The rhenium content is 100% minus the sum of the measured values of the impurity elements listed in the table. |

|||||

|

No. |

Elements |

%wt |

No. |

Elements |

%wt |

|

1 |

C |

0.0015 |

3 |

O |

0.030 |

|

2 |

H |

0.0015 |

|

|