Refractory Metal W with high hardness

Description

Refractory Metal W is a highly sought-after material in various industries due to its unique properties. It has exceptional high-temperature resistance, making it ideal for use in applications that require withstanding extreme heat. Additionally, it has high hardness, which makes it suitable for use in high-wear applications.

One of the common applications of Refractory Metal W is in the manufacture of thin-walled tungsten collimator grids. These grids are essential in medical imaging applications, as they help to shape the radiation beams used in diagnostic procedures.

Another application of Refractory Metal W is in the production of heat sinks for deflector filters of thermonuclear fusion reactors. The heat sinks help to dissipate the heat generated during the fusion reaction, which is essential for maintaining stable reactor conditions.

Finally, Refractory Metal W is used in the production of high-temperature tungsten nozzles for aero engines. These nozzles are subject to extreme temperatures and high levels of wear, making the high hardness and temperature resistance of Refractory Metal W ideal for this application.

Chemistry

| Element | Al | Si | Cr | Fe | Cu | O | |

|---|---|---|---|---|---|---|---|

| Mass (%) | <0.001 | <0.001 | <0.001 | <0.005 | <0.05 | <0.01 | |

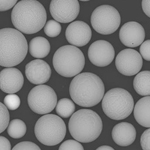

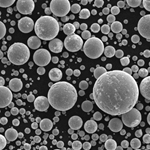

Physical property

| PSD | Flow Rate (sec/50g) | Apparent Density (g/cm3) | Tap Density(g/cm3) | Sphericity | |

|---|---|---|---|---|---|

| 15-45μm | ≤6.0s/50g | ≥10.5g/cm3 | ≥12.5g/cm3 | ≥98.0% | |

SLM Mechanical property

| Elastic modulus(GPa) | 395 | |

| Tensile strength(MPa) | 4000 | |