Nickel Base Alloy with oxidation and corrosion resistant

Application

Nickel base alloy powder is a high-performance material that is widely used in various industries, especially in high-temperature and corrosive environments. Its good corrosion resistance and high-temperature oxidation resistance make it a popular choice for coatings on steel and low alloy steel parts under high-temperature conditions. It is also used as a bonding phase of carbide coating, making it an ideal choice for wear-resistant applications.

Properties

The powder is composed of nickel, chromium, and other elements, which give it excellent corrosion resistance and high-temperature stability. The powder can form a coating that can work at temperatures up to 980ºC, making it suitable for use in harsh environments. The coating also has good toughness and mechanical performance, which makes it ideal for use in wear-resistant applications.

Manufacturing

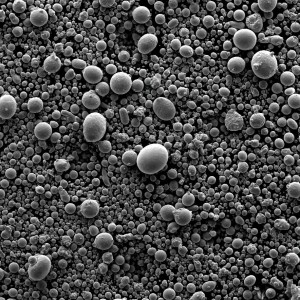

The nickel base alloy powder is produced using a gas atomization process. The process involves melting the raw materials and then atomizing them into a fine powder using high-pressure gas. The resulting powder has a uniform particle size and good flowability, which makes it easy to handle and process.

Usage

Nickel base alloy powder is widely used in various industries, including aerospace, power generation, and chemical processing. It is commonly used as a coating material to protect steel and low alloy steel parts under high-temperature and corrosive conditions. It is also used as a bonding phase of carbide coating, making it ideal for wear-resistant applications. The powder can be applied using various thermal spray processes, including flame spray, plasma spray, and high-velocity oxy-fuel (HVOF) spray.

Conclusion

Nickel base alloy powder is a high-performance material that is widely used in various industries for its excellent corrosion resistance and high-temperature oxidation resistance. The gas atomization process ensures that the powder has a uniform particle size and good flowability, making it easy to handle and process. Its high-temperature stability, toughness, and mechanical performance make it an ideal choice for use in harsh environments and wear-resistant applications.

Similar products

| Brand | Product Name | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-3061 | NiCr-50/50 | |||||

| KF-306 | NiCr-80/20 | 250251 | 43 / 5640 / 4535 | NI105 / NI106 /NI107 / 1262 | 98 | |

| HastelloyC22 | ||||||

| HastelloyC276 | 409 | 4276 | NI544 / 1269 | C276 | ||

| Inconel 718 | 407 | 1006 | NI202 / 1278 | 718 | ||

| Inconel 625 | 380 | 1005 | NI328 / 1265 | 625 |

Specification

| Brand | Product Name | Chemistry (wt%) | Hardness | Temperature | Properties & Application | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr | Al | W | Mo | Fe | Co | Nb | Ni | |||||

| KF-306 | NiCr-80/20 | 20 | Bal. | HRC 20 | ≤ 980ºC | •APS, HVOF Spherical

•Good corrosion resistance |

||||||

| Hastelloy | 21 | 3 | 15 | 2 | 2 | Bal. | HRC 20 | ≤ 900ºC | •High corrosive environment spraying | |||

| Inconel 718 | 20 | 3 | 18 | 1 | 5 | Bal. | HRC 40 | ≤ 950ºC | •Gas turbine •liquid fuel rocket •Low temperature engineering •Acid environment •Nuclear engineering |

|||

| Inconel 625 | 22 | 9 | 5 | 4 | Bal. | HRC 20 | ≤ 950ºC | •Absorption tower •Reheater •Flue gas inlet damper •Agitator •Deflector |

||||