Ni-Graphite Cladding powder with electrical conductivity

Description

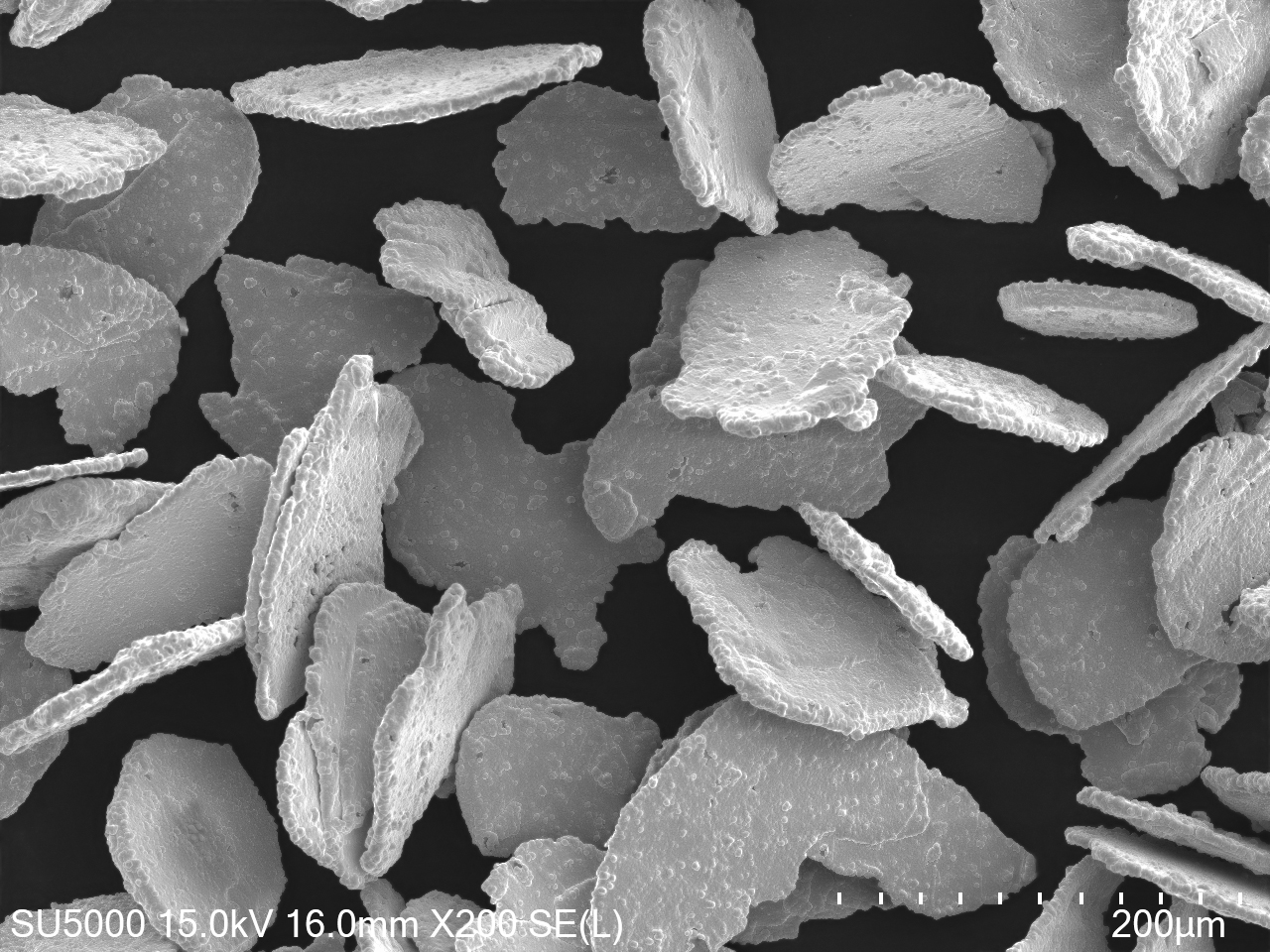

Ni-Graphite Cladding powder is a highly specialized material that has been engineered to provide superior performance in demanding industrial applications. This innovative powder is chemically clad with a high concentration of nickel and graphite, making it an ideal choice for use in wearing materials of turbo compressors, nickel alloy, and steel parts.

One of the key features of Ni-Graphite Cladding powder is its high graphite content. This attribute enhances the lubrication performance of the powder, making it a popular choice for use in titanium parts that lack an edge. Additionally, the high nickel content of the powder improves its erosion resistance, ensuring that it provides optimal performance in harsh industrial environments.

Ni-Graphite Cladding powder is available in two different formulations: KF-21 Ni-Graphite 75/25 and KF-22 Ni-Graphite 60/40. These two formulations have different nickel and graphite content ratios, making them suitable for different types of industrial applications. For example, KF-21 Ni-Graphite 75/25 has a higher nickel content, making it ideal for use in applications that require superior erosion resistance.

In addition to its high-performance characteristics, Ni-Graphite Cladding powder is also highly versatile. It can be used in a wide range of industrial applications, including turbo compressors, nickel alloy, and steel parts. Furthermore, its flame resistance and maximum operating temperature of 480°C make it a reliable choice for use in high-temperature applications.

When it comes to choosing the right Ni-Graphite Cladding powder for your industrial application, it is important to consider the specific OEM specifications of your equipment. KF-21 is similar to AMPERIT 205, METCO/AMDRY 307NS, PRAXAIR NI-114, and PAC 138, while KF-22 is similar to AMPERIT 200 and Durabrade 2211.

In conclusion, Ni-Graphite Cladding powder is a highly specialized material that provides superior performance in demanding industrial applications. Its high graphite content and high nickel content make it an ideal choice for use in wearing materials of turbo compressors, nickel alloy, and steel parts. With its versatility, flame resistance, and high operating temperature, Ni-Graphite Cladding powder is a reliable choice for a wide range of industrial applications.

Similar products

| Brand | Product Name | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-21T/R | Ni-Graphite 75/25 | 205 | 307NS | NI-114 | 138 | |

| KF-22T/R | Ni-Graphite 60/40 | 200 | Durabrade 2211 |

Specification

| Brand | Product Name | Chemistry (wt%) | Hardness | Temperature | Properties & Application | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | Bal. | HRC 20 | ≤ 800ºC | •Flame, APS, Max. operating temperature 650°C.

•Dense and machinable oxidation resistant and wear resistant coating. |

||||||||

| KF-6 | NiAl95/5 | 5 | Bal. | HRC 20 | ≤ 800ºC | •Flame, APS, HVOF, Max. operating temperature 800°C

•Dense and machinable oxidation resistant and wear resistant coating |

||||||||

| KF-20 | Ni-MoS₂ | 22 | Bal. | HRC 20 | ≤ 500ºC | •Used for movable sealing parts and grindable sealing rings •It can be used as low friction material |

||||||||

| KF-21T | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | •Flame, Max. operating temperature 480°C 1. Wearing materials of turbo compressor •Applicable to nickel alloy and steel parts •Products with high graphite content are suitable for titanium parts without edge •High graphite content will enhance the lubrication performance •High nickel content will improve erosion resistance •Similar products are different due to different OEM specifications |

||||||||

| KF-22T/R | Ni-Graphite 60/40 | 50 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-45 | Ni-Al2O3 77/23 | 23 | Bal. | HRC 40 | ≤ 800ºC | •Flame,APS, irregular

•It can be used to melting crucible, terminal sealing surface and mold surface as protective layer |

||||||||

| KF-56 | Ni-WC 16/84 | Bal. | 12 | HRC 62 | ≤ 400ºC | •Flame,APS, irregular

•Resistance to hammering, erosion, abrasion and sliding abrasion |

||||||||

| KF-50 | Ni-WC10/90 | Bal. | 10 | HRC 62 | ≤ 400ºC | •Flame, irregular

•Resistance to hammering, erosion, abrasion and sliding abrasion |

||||||||

| KF-91Fe | Fe-WC | 4 | 27 | 9.5 | Bal. | 5.5 | HRC 40 | ≤ 550ºC | •Flame, APS, irregular, Max. operating temperature 815°C.

•Wear resistant coating material, which can be used for tank brake pad repair |

|||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | Bal. | HRC 20 | ≤ 800ºC | •Flame, APS, Max. operating temperature 980°C.

•Plasma spraying with self bonding |

|||||||

| KF-113A | NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤ 900ºC | •APS,HVOF, irregular, Max. operating temperature 980°C.

•It is applicable to the repair of high temperature bonding layer or wear / improperly processed parts |

|||||||||

| KF-133 | NiMoAl | 5 | 5 | Bal. | HRC 20 | ≤ 650ºC | •Self bonding, common hard coating for bearing application •Tough, with good corrosion resistance and impact performance •Used for machine parts, bearing seat and valve |

|||||||

| KF-31 | Ni-Diatomite 75/25 | •Flame,APS, irregular, Max. operating temperature 650°C.

•For grindable seal coating, including movable seal parts, grindable seal rings, low friction materials |

||||||||||||