Cobalt Base Alloy with resistant to wear and corrosion

Description

KF-3321 is a cobalt-based alloy powder with excellent wear resistance and high-temperature oxidation resistance. It is composed of cobalt, chromium, tungsten, nickel, silicon, and carbon, and may also contain small amounts of aluminum, niobium, tantalum, and other alloy elements.

Powder Properties

Particle Size: KF-3321 has a particle size range of -140 to +325 mesh, which makes it suitable for various applications where a fine particle size is required.

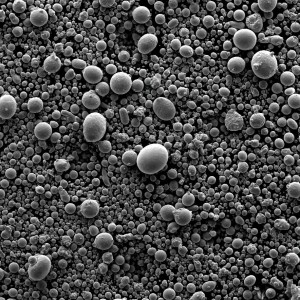

Type: KF-3321 is a gas atomized powder, which means it is produced by melting the alloy and then atomizing it with high-pressure gas. This results in a spherical powder shape, which provides good flowability and packing density.

Composition: KF-3321 is a cobalt-based alloy powder that contains a high percentage of cobalt, which gives it excellent wear resistance. The addition of chromium and tungsten further improves its wear resistance and high-temperature oxidation resistance. Nickel, silicon, and carbon provide additional strength and corrosion resistance to the alloy.

Application

KF-3321 is a versatile alloy powder that can be used in various industries for applications that require excellent wear resistance and high-temperature oxidation resistance. Some common applications include:

High-temperature pressure valves: KF-3321's high-temperature oxidation resistance makes it an ideal material for high-temperature pressure valves.

Saw teeth: KF-3321's wear resistance and toughness make it suitable for use in saw teeth, which require a hard material that can withstand the stress and strain of cutting.

Extrusion screws: KF-3321's wear resistance and high-temperature oxidation resistance make it a good choice for use in extrusion screws, which require a material that can withstand the high temperatures and pressures of the extrusion process.

Similar to St12: KF-3321 has similar properties to St12, a low carbon steel commonly used in the automotive industry. However, KF-3321 has much better wear resistance and high-temperature oxidation resistance than St12, making it a superior choice for applications that require high wear resistance and high-temperature stability.

Overall, KF-3321 is a high-performance alloy powder that offers excellent wear resistance and high-temperature oxidation resistance. Its versatile properties make it suitable for a wide range of applications in various industries.

Similar products

| Brand | Product Name | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-331 | CoCrMoSi | 340 | 66 / 3002 | CO109 / 1247 | T400 | |

| KF-333 | CoCrMoSi | 342 | 68 / 3001 / 4800 | CO111 / 1248 | T800 | |

| KF-332 | CoCrWCNiSi | |||||

| KF-3321 | CoCrWCNiSi | |||||

| KF-3322 | CoCrWCNiSi | Similar to 344 | 4060 | CO106 1256 | 6 46 | |

| KF-3323 | CoCrWCNiSi | |||||

| KF-3324 | CoCrWCNiSi | 344 | 45 x40 | CO105 / CO285 | 90 | |

| KF-3325 | CoCrWCNiSi |

Specification

| Brand | Product Name | Chemistry (wt%) | Hardness | Temperature | Properties & Application | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr | W | C | Ni | Si | B | Mo | Co | |||||

| KF-331 | CoCrMoSi | 8 | 2.6 | 28 | Bal. | HRC 54 | ≤ 840ºC | •Wear resistance, scratch resistance

•Corrosion resistance |

||||

| KF-333 | CoCrMoSi | 17.5 | 3.4 | 35 | Bal. | HRC53 | ≤ 840ºC | •Wear resistance, scratch resistance

•Corrosion resistance |

||||

| KF-332 | CoCrWCNiSi | 25 | 7.5 | 0.8 | 10 | 1 | Bal. | HRC 30 | ≤ 840ºC | •Valve seat •Bearing •Blade •Similar to St1 |

||

| KF-3321 | CoCrWCNiSi | 30 | 4 | 1.5 | 3 | 1.4 | 4 | Bal. | HRC45 | ≤ 840ºC | •PTA, APS, HVOF, laser cladding, spherical

•High temperature pressure valves, saw teeth, extrusion screws •Similar to St12 |

|

| KF-3322 | CoCrWCNiSi | 30 | 4.5 | 1 | 3 | 1.4 | Bal. | HRC 40 | ≤ 840ºC | •PTA, APS, HVOF, laser cladding, spherical

•Engine valves, high temperature pressure values, turbo engine blades •Similar to St6 •Good wear resistance in high temperature |

||

| KF-3323 | CoCrWCNiSi | 28 | 0.25 | 3 | 1 | 5.5 | Bal. | HRC55 | ≤ 840ºC | •Turbine blades

•Fluid valves •Valve seat |

||

| KF-3324 | CoCrWCNiSi | 25.5 | 7.5 | 0.5 | 10.5 | 1 | Bal. | HRC 30 | ≤ 840ºC | •Extrusion molds

•Gas turbine blades |

||

| KF-3325 | CoCrWCNiSi | 21.0 | 5 | 0.1 | 1 | 1.6 | 2.4 | Bal. | HRC50 | ≤ 840ºC | •PTA, APS, HVOF, laser cladding, spherical

•High temperature wear resistance •Motorcycle valves •Self-fluxing |

|